Product Highlight

Servitec S

Our vacuum spray deaeration/make-up highlight

This year the technology of vacuum spray-tube degassing will be 20 years old and we are celebrating this with a special highlight: the new Servitec S. It is the ideal choice for medium-sized systems with a water volume of up to 6 m³.

Cyclone diameter from 0.01 to 3 m c. Cut diameter from 0.2 to 20 mm d. Cyclone efficiency. Pressure drop from 10 to 10 000 Pa To run the application, the user enters to enter 2 or 3 variables and the other parameters are then calculated. A simple and user friendly software. The software consists of tables into wich the system. The Computer-Aided Design ('CAD') files and all associated content posted to this website are created, uploaded, managed and owned by third party users. Each CAD and any associated text, image or data is in no way sponsored by or affiliated with any company, organization or real-world item, product, or good it may purport to portray. Here is a hydrocyclone sizing calculator with immediate access to all design equations needed for your hydrocyclone design calculation in an online XLS spreadsheet format. Based on first principles of hydrocyclone theory and equations, this quasi design software lets you enter all cyclone design parameters such as cut size, D50, D60 (efficiency calculation), graphs your results. DataSuite software setup.exe. Installation files for DataSuite software, v2.5.0.0, supporting DaqLink, DataNet, MicroLite II, MicroLogPRO II and PicoLite data loggers. Begin Software Download. Presens Fibox 3 (oxyview) Begin Software Download. Basic ComSoft 5 software. Installation files for Testo 174,175, 176 dataloggers.

Foreign particles and substances can significantly reduce the performance and service life of heating systems and increase service intervals. Our solutions can help to prevent this and achieve optimum operating conditions.

Reflex separation technology uses mechanical separation processes, for which no auxiliary energy is needed. Reflex produces models for dirt and sludge as well as for micro-bubbles and free air. The separation includes micro-bubbles, air bubbles and free air, particularly during filling and draining processes.

Servitec degassing systems even degas dissolved gases in a vacuum. The process is electronically monitored and optimized by a Reflex Control unit.

Energy efficiency brochure better water for heating and cooling systems. Better air for the Environment.

Download

Product brochure degassing systems & separation technology

Download

Separation technology for vertical power lines

Particulate pollution has been increasing over the past few years. Industries has been trying to develop new methods and devices to remove particles from exhaust gas. Cyclone separator is a device with no moving parts is used to separate dust particles from exhaust gas. But, the main drawback is the increasing pressure drop. From the literature review, it is found that pressure drop is caused due to geometrical parameters, surface texture and nature of the particle flow. In order to reduce the pressure drop the above parameters needs to be modified. The modified design is modeled and analyzed with the help of CFD and the difference is noted.

These days in businesses one of the fundamental ecological issue is particulate contamination. The residue particles originating from the ventures are inclined to a few wellbeing risks. The government is endeavoring to grow new strategies to expel the particles from the fumes gases. So it can turn into the most secure point of confinement, and it might give less damage to living creatures. Particulate pollution has been increased and it has been a concern for a few years in order to minimize particulate pollution, several dust collector has come into the market contamination, a few residue authority has come into the market. Most residue authorities has their own particular determine. There are distinctive sorts of residue authorities accessible in the market. The parameters that a dust collectors should fulfill are

Any subject

Min. 3-hour delivery

Pay if satisfied

Get your price1. Less maintenance;

2. Temperature resistance;

3. Pressure resistance.

Cyclone seperator

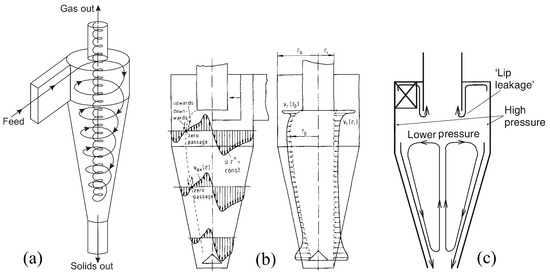

Cyclone seperator is a device which satisfy many of the condition, it is a stationary device and has moving parts. It is used to separate particle in the range 10Ој – 100Ој.There are different types of cyclone. But the cyclone with tangential inlet is quite popular (Irfan Karagoz & Atakan Avci, 2007). Cyclone separator is dust collection which is used for separating particles from exhaust gases in industries. It has its own place in the industry become of some of its simple but efficient benefits like lack of moving parts and least maintenance when compared to other similar dust collectors in the industry it is generally referred as the masterpiece of an engineer. Its operation is relatively simple yet efficient. It belongs to the group of centrifugal seperators and it operates with centrifugal force. It has no other equipment’s such as filters, etc. Its working depends mainly on the shape of the equipment which enables rotational effects and creates vortex to separate particle from gaseous mixtures. It can also separate liquids from gaseous mixtures. It is used not only for separating the particles but also for classifying the particles based on its size, nature of the particles. It separate the particles within the range of 10Ој – 100Ој.It is commonly used in power plants, extraction plants, cement industry, etc. It is also used in chemical industry, food industry. Nowadays it is used as vacuum cleaners in as domestic applications.

The execution of a cyclone seperator relies upon two factors specifically particle accumulation effectiveness and pressure drop. For instance on account of incompressible fluid stream in a tube shaped the outlet velocity will be lesser than its inlet speed, which is because of frictional losses in the pipe. It can be altered by changing the surface conditions.

Operation

Cyclone seperator works on the principle of centrifugal separation. The exhaust gas coming from the factories has be treated since it contains dust particles. This dust laden gas is made to pass through the tangential inlet. Then it reaches the cylinder portion. Now the linear flow is transformed into swirling motion, i.e. a swirl (outer vortex) is created. Due to the surface roughness of cylinder and cone portion particles come into contact with the wall and they fall into the collector (Alex C. Hoffmann, 2005). The gas due to the centrifugal force moves towards the outer boundary and the outer vortex is maintained. Simultaneously the swirl continues towards the end and it reverses its direction and inner vortex is created (T. G. Chuah 2003). The upward movement is mainly due to the low density of the gas and we know that gas always travels from low pressure to high pressure. The cleaner gas comes out of the vortex finder.

Parameters used to design cyclone separator are height in inlet, cylindrical and conical section. Width of inlet, exit diameter and vortex finder diameter.

Flow in cyclone seperator

The flow of a cyclone seperator is mainly swirling flow which is obtained due to the geometry of the equipment. There are two types of vortex occurring in a cyclone an outer vortex which is created during the flow from inlet to collector in the downward direction whereas the inner vortex is created during the flow from collector to the vortex finder in the upward direction. Swirling Flow Real Vortex flow This types of flow takes place in different types of equipment such as cyclones, hydrocyclones, etc. The major classification of swirling flow are:

A. Forced Vortex Flow:

A swirling flow defined as tangential velocity distribution of a rotating solid body

B. Free Vortex Flow

A flow in which fluid swirl without friction. In swirling flow the tangential velocity distribution will occur in-between these two ends. Consider that the swirling fluid behaves like a solid body has an infinite viscosity. Then, the fluid layers at different radii won’t have shearing motion between them. Here, the fluid elements at radial positions are forced which will have the same angular velocity.

Performance of cyclone separators

There are two performance indicators for the functioning of cyclone separators. They are:

A. Pressure Drop

In general, the term pressure drop means drop in total pressure i.e. Static pressure and Dynamic pressure. In other words the pressure lost during the flow between inlet and outlet. It occurs mainly due to the frictional losses in the body of the cyclone. It is very difficult to measure pressure drop due to the presence of swirl in the exiting gas (Khairy Elsayed 2011). Moreover the static pressure can be measured easily whereas the dynamic pressure at the exit is difficult to measure experimentally. The pressure drop over a cyclone is normally divided in three sections:

1. Losses in the entry,

2. Losses in the separation space (the main cyclone body), and

3. Losses in the vortex finder.

The entry losses in cyclones with tangential inlets are negligible since the flow is linear and it moves to the main cyclone body without much obstructions. Once the flow enters the cyclone body the linear flow transforms into a swirl flow due to the shape of the body. So the dynamic pressure increases accordingly. But this increase in dynamic pressure is lost due to the friction in the walls. Therefore the losses in the cyclone body is much higher to the other section. In the vortex finder the clean gas comes out through it but due to the swirl present in the flow some pressure is lost. Thus these are the main sections of pressure drop.

B. Pressure drop model

The velocity distribution in the cyclone is formulated by the Stairmand and calculated the losses of pressure in the model. It is recommended to use vortex finder for the recovery of static pressure reduction formulae for drop in cyclone pressure is given by Iozia and Leith.

V. Factors affecting the cyclone performance

A. The inlet section pressure drop

The inlet sections of the cyclone separators is one of the primary areas of concern after the study of vortex length by many experts. The cyclone has two spiral motions it forms two vortexes, outer vortex and inner vortex. In the tangential reverse flow cyclone, the outer vortex weakens when it reaches the dust collector and changes its direction at a certain axial. The inlet dimensions has given a direct effect on pressure drop. This shows that the inlet area increases with the decrease in pressure drop. The effect of inlet dimensions has been investigated by several researchers.

B. The effect of the inlet height

While increasing the inlet height there is a pressure drop in cyclone separator. The value of 0.25 a/D 0.4 it is explained in three main categories.

(1) By increasing the inlet dimension there is a pressure drop in the cyclone separator.

(2) Increasing in the inlet height decreases the pressure drop in the cyclone body.

(3) Vortex finder which helps to energy loss makes the pressure drop in cyclone separator. The increasing the cyclone inlet height makes the total pressure drop.

C. The inlet width effect

While increasing the inlet width there is a pressure drop in cyclone separator. The value of b/D 0.15 plays the major role in reduction of pressure.

D. Cyclone height

As is obvious from the greatest velocity falls with expanding violent model height. All comparable in cyclone, the pressure drop does not separate with height. The sharp abatement of the Euler number with cyclone B1 and B2 will likewise tangential velocity diminish. Toward the starting, the friction of wall impact is little in correlation with the impact of vortex quality. For longer twisters, this impact ends up bigger. This clarifies the little variety of the Euler number with the barrel height for h/D > 1.8, which is obvious from where the most extreme digressive speed of twisters B3 and B4 are close.

E. The cone tip diameter

Cyclone Separator Design software, free download Windows 7

Shape of cone can be determined by fixing other dimensions. There is only few information are there to find the effect of changes in it.

F. The vortex finder dimensions

The length of the vortex finder directly affects the performance of the cyclone and the pressure drop. The ratio of the cyclone body diameters and the vortex finder diameter. Dx/D affected the efficiency of the collection and pressure drop of cyclones and proposed an energy effective cyclone. In the vortex finder diameter decreases, the downward flow too decreases and increases the tangential velocities but the pressure drop increments.

VI. Modeling of cyclone separator

The modelling of cyclone separator can be done using any CAD modelling software, shown in fig 1. For example Solidworks, Catia, ProE, etc. Here it is done using Solidworks Table 1 Modeling in solid works Parameters Old Design New Design D 1 1 Dx 0.43 0.43 H 2 2 Hc 1.4 1.068 S 0.57 0.57 Dd 0.35 0.35 a .34 0.31889 b .24 0.2179 1424 Pa 1299 Pa To design the cyclone the diameter (D) is considered as 100 mm. Fig.1. CAD model of cyclone separator

VII. CFD analysis

It is an easy way of calculating flow pattern, separation efficiency, drop in pressure cyclones and swirl tubes. In CFD, the equations governing the flow of the gas: the Navier-Stokes equations, are written in a “finite difference” form, and calculated with the help of computer on a grid of points. The flow of gas in the separator is turbulent but this creates a problem when using CFD. In general, if the computational grid could be made fine enough, CFD could be used to solve the Navier-Stokes equations directly, and the turbulence would spontaneously rise in the simulation (F. Boysan, 1982). In “direct turbulence modeling” such CFD simulations are already being carried out in a small, modest geometries, and this field is developing fast as the computing power of the computer increases. However, in real processing equipments, this is not possible yet because the number of grid points and time steps required is too high.

A. Numerical Settings

The boundary conditions for the cyclone separator are given as follows:

Cyclone Separator Design software, free download 2020

Inlet as Velocity inlet – 18 m/s

Air density – 1.0 kg/m3

Dynamic viscosity – 1.4857Pa s

turbulent intensity = 5%

Outlet Pressure Outlet

Remaining surfaces – Wall

The models available are standard k-Оµ model, complicated Reynolds stress model (RSM) and large eddy simulation (LES) methodology which is alternative for RANS models.

B. Selection of the discretization schemes

By selecting the simulation results the mesh plays the vital role in it. The rate of kinetic energy dissipation, momentum, pressure and pressure velocity coupling are important factors in the solver. The SIMPLEC model is the benefit of solution converging. In the pressure staggering interpolation can locate the mean speed profiles static pressure distribution and the pressure drop in the cyclone separator with the test esteems. For swirling flows this plan is additionally suggested by the fluent. For energy, the plan utilized is quadratic upwind differencing for the stream in violent wind separators. The second-order upwind plan is utilized for the discretization of kinetic energy and its scattering rate condition. The first order up wind scheme is used in Reynolds stress equations.

The Reynolds stress turbulence model has been utilized to characterize the turbulence qualities in the cyclone separators. FEM finite element method is used to mesh the model by using SIMPLEC i.e semi implicit method for pressure linked equation consistent. From the time 0.0001s the Reynolds turbulence model is noted. The grid refinement study The aggregate number of 134758 hexahedral cells for the Stairmand cyclone and 381710 hexahedral cells for the new outline are adequate to acquire a mesh independent solution, and further work refinement yields just little, unimportant changes in the numerical solution.

At the point when ANSYS FLUENT illuminates the equation which are dependent of time formulates the implicit, number of iterations may important at every time step. This factor makes good for the iterations per time step

C. Solution

The solution is converged at the 355th iteration as shown in the fig 2. The fluid inside the cyclone follows a path which is shown in vector. The flow is working as like the flow that explained in cyclone separator. The different ranges of velocity are shown in left side bar and the values also observed there. The velocity gradients are observed by the differentiation of color. At the z=0 contour is plotted to show and understand the flow path inside the cyclone. The figure of velocity and pressure contours is used to observe the flow path inside the cyclone separator.

Cyclone Separator Design software, free download 2018

VIII. Results and discussions

Cyclone Separator Design software, free download For Beginners

Industrial Cyclone Dust Separator Design

From the above analysis cone height plays major role inf the cyclone. The pressure gradients are occur along the x-axis. From Fig 13, the lowest pressure is in the center protion(x=0). The pressure varies in the radial direction which is represented in the graph. The variation of pressure is explained by the parabolic curve. The cyclone velocity also varies as inverted parabolic shape which represents high and low at the wall. The curve may be M shape or reversed W shape. The velocity will be max in center portion and wall.

Thus we have concluded that cyclone separator is one of the most significant emission control devices. The fact preventing its use is the increasing pressure drop. From the literature survey, we find that pressure drop can be decreased by changing the geometrical dimensions. Both the existing design and new designed, modeled and analyzed with ANSYS FLUENT software. From the contours, we found that total pressure decreases i.e. pressure drop also decreases for changes in design.